Contact Us

The Engineering, Procurement, Construction (EPC) and Operations & Maintenance (O&M) of 10,000 BPD Very high sour oil early production facility including the following major processing equipment:

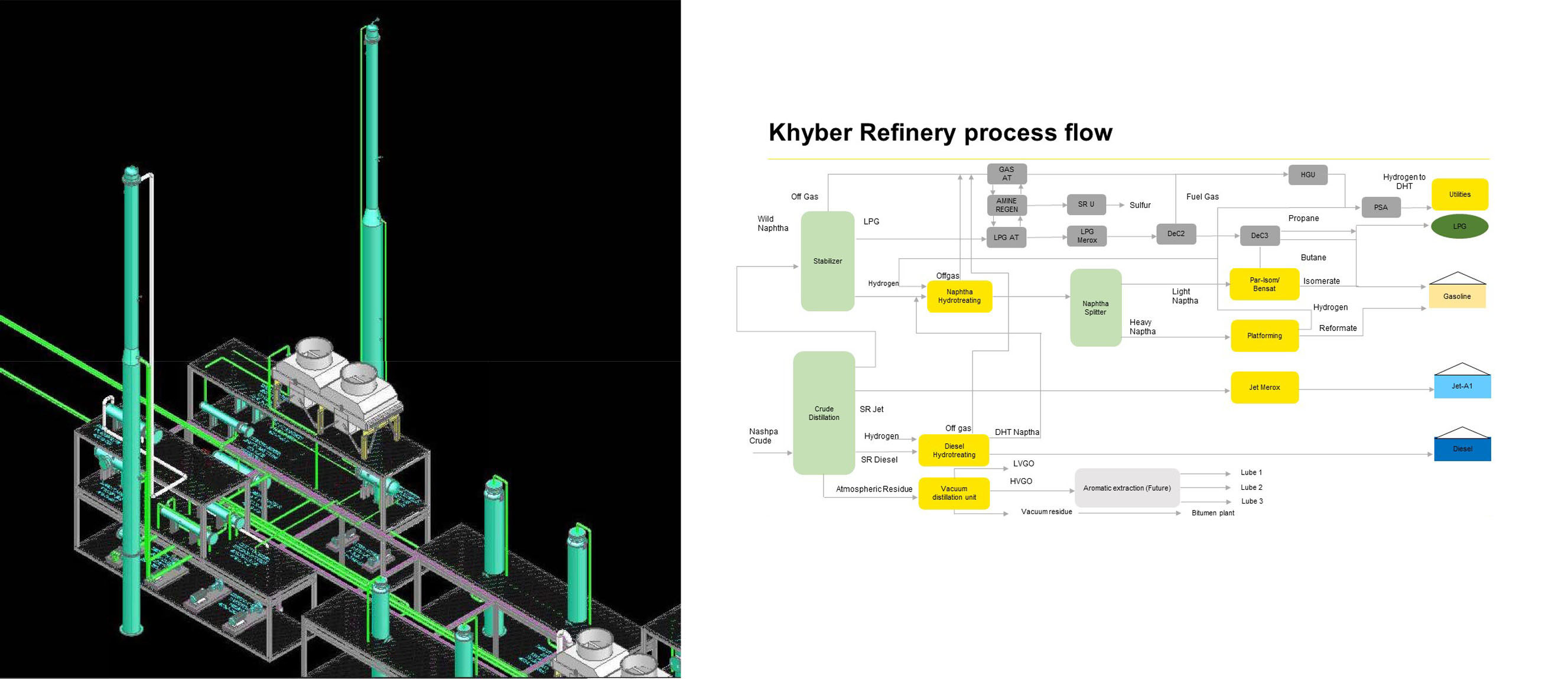

The Engineering, Procurement, Construction and Commissioning of 20,000 BPD Refinery including CDU, NHT, Isomerization Unit, Diesel HT, Kerosene Treater, Utilities and Tankage under Process Licensor

The Revamp, Optimization and Commissioning of Egbaoma Gas Processing Plant (100 Ton/day LPG Extraction Facility) including engineering, project management, procurement and fabrication, construction management, commissioning and O&M in Ebedei, Ukwuani Local Government area of Delta State – Nigeria

Design, Project Management, Engineering, Procurement, Supply, Installation, Commissioning and Testing of 2 x 35 MMSCFD Glycol Dehydration Type Natural Gas Process Plant including Gas Gathering Pipelines and Associated Fields on Turnkey basis.

Sour Gas Processing Facility, 35 ppm H2S and 3.5 mol % CO2, Three Production Wells, 15 km Pipeline, Inlet Separator, Amine Gas Sweetening, Gas Dehydration, HCDP Packages, Condensate Stabilization, Metering Stations, Gas Compression Stations, 8 km Road, Housing Facilities, Condensate Loading Station, Condensate Storage, Utilities, Plant Electrical,Automation & Control

Engineering, Procurement, Fabrication & Construction/commissioning management of 120 MMSCFD Gas processing plant (Modular packages)

Design, Procurement and Fabrication of Crude Oil Heating, Separation and Flare System for Gharib Treatment Plant at the Eastern Desert Field comprising of 2 X 15000 BOPD Sour Oil (7.2 Mol% H2S and 1.93 Mol% CO2) Processing trains

Design Engineering, Project Management, Procurement, Fabrication and Commissioning of Six (06) Trains of 20000 BOPD Sour Crude (2.0 Mol% H2S and 2.3 Mol% CO2) Field Separation Units (Two (02) phase separators, crude transfer pumps, flare system. IA system, local PLC based control system and MCC)

Design, Detailed Engineering and Fabrication of two (2) Glycol Dehydration Units (TEG and EG) for the Treatment of Flare Gas. Additional scope also included two (2) Separator Packages, Pumping Skid, Condensate Stabilization Unit, Heat Exchangers and Control and Safety Shutdown System

Design, Engineering, Procurement, Supply, Installation, Commissioning and Testing of 10,000 BOPD Sour Crude (2.5 Mol% H2S) Early Production Facilities including Complete Oil Treatment with Sour Gas Stripping Columns, Water Treatment and High Pressure Reinjection and Camp Facilities and All Associated Utilities on Turnkey Basis.

Sour Crude Field (100 ppm H2S) including Chemical Injection Package (Corrosion, Asphaltene, Scale, Hydrate) Closed Drain System, Pig Launchers / Receivers, Installation of Pipelines and Engineering, Supply, Commissioning and Testing of Accessories for Safe Operation, Production Header and Test Header, Corrosion Protection System, Electrical Items, Instrumentation and control, Telecommunication, Civil Works

Sour Crude Field (100 ppm H2S) including Chemical Injection Package (Corrosion, Asphaltene, Scale, Hydrate) Closed Drain System, Pig Launchers / Receivers, Installation of Pipelines and Engineering, Supply, Commissioning and Testing of Accessories for Safe Operation, Production Header and Test Header, Corrosion Protection System, Electrical Items, Instrumentation and control, Telecommunication, Civil Works

High sour content of process gas viz - 600 ppm H2S and 4 % CO2, Treatment included Corrosion Inhibitor Injection, MDEA Gas Sweetening, Sour Water Stripping (with Reboiler)

Glycol Dehydration Package, Amine Sweetening, Gas Metering, Condensate Storage, Sour Water Treatment, Fuel Gas Conditioning, Three Phase Separator, Corrosion Inhibitor Heat Medium Package, Incinerator, DCS, MCC, Wellhead Pneumatic Panels, Synchronization Panel, Instrument Air Package.

The project scope was for the engineering, procurement and commissioning of a LPG Production Facility including inlet separator train, Molecular Sieve Dehydration Units, JT Valve Expansion Units, Propane Refrigeration Packages, LPG Fractionation (Deethanizer and Debutanizer) and plant automation and control

The SPEC Group has received a contract for the engineering, procurement and commissioning of oily water and produced treatment project with 360 m3/day including 6 CPI separators, 18 transfer pumping stations, two IGF units, Compaction packages and chemical injection units. The end results is water with oil content below 5 ppm in product stream.

The project scope was for the engineering, project management, procurement, construction supervision and commissioning of a complete 100 ton/day LPG Production, storage and Loading Facility inclusive of early production Facility, Booster Compressors, Molecular Sieve Dehydration Units, JT Valve Package, Fractionation Units

The project scope was for the engineering, project management, procurement, construction supervision and commissioning of a two train 25,000 BOPD Crude Processing facility which comprised of separation trains, water bath heaters, oil dehydrators, oil stabilization units, sour gas strippers and crude export pumps. The facility also treated a 25 MMSCFD Gas Dehydration and Dew Point Control Units along with a 10,000 BWPD CPI and IGF water treatment package. Complete Automation was also included in scope of supply.

High sour content of process gas viz. 600 ppm H2S and 6% CO2. Treatment included Corrosion Inhibitor Injection, MDEA Gas Sweetening, Sour Crude and Sour Water Stripping (with Reboiler)

The project scope was for the engineering, procurement, construction and commissioning of a 30 MMSCFD sour gas processing facility complete a Amine Gas Sweetening Unit, Glycol Dehydration Unit, HCDPC unit, Metering Packages, Water Treatment Packages, Automation and all associated utilities.

The project scope was engineering, procurement and commissioning of an 10000 BOPD EPF and treatment of associated Gas with TEG Dehydration Unit.